The tensile properties of all weld joints showed a relative correspondence to the variation of the hardness in the weld zone. From the investigation it is found that the joints fabricated at a traverse speed of 40mm/min resulted in better mechanical properties compared to other traverse speeds. Mechanical and microstructure analysis has been performed to evaluate the characteristics of friction stir welded copper. The defect free welds were obtained at a tool rotational speed of 900 rpm and traverse speed of 25, 31.5 and 40 mm/min respectively. The main objective of this investigation is to use FSW for joining of 3 mm thick copper sheet using taper cylindrical tool pin profile. This process uses a non-consumable tool to generate frictional heat in the abutting surfaces.

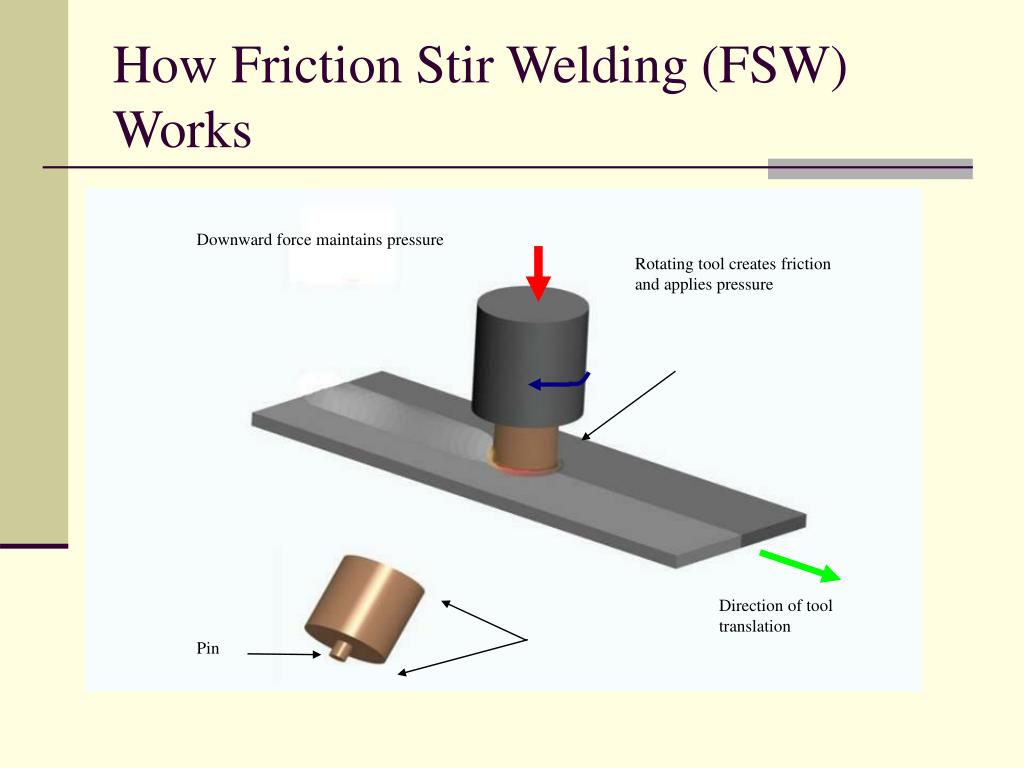

FSW is an emerging solid state joining process in which the material that is being welded does not melt and recast. Friction Stir Welding (FSW) is an excellent alternative for joining of these materials against fusion joining. This paper focus on Mechanical properties evaluation and predicting the process parameters in varying rotational and welding speeds of friction-stir welding for the dissimilar precipitation hardenable aluminium alloys ie., between 6xxx (Al-Mg-Si) and 7xxx (Al-Zn-Mg).įusion welding of copper and its alloys tends to degrade the mechanical strength at the weld joint area due to high thermal diffusivity and high melting point. The welding parameters such as tool rotational speed, welding speed, axial force etc., and tool pin profile play a major role in deciding the joint strength.

the joint is performed in the solid-state and excessive micro structural degradation of the weld zone is avoided. The major advantage in FSW process is that the maximum temperature reached is less than 80% of the melting temperature (TM), i.e. Compared to the fusion welding processes that are routinely used for joining structural aluminium alloys, friction stir welding (FSW) process is an emerging solid state joining process was invented in 1991 by TWI, in which the material that is being welded does not melt and recast. Therefore welding processes have proven more attractive, and there is an urgency to study their potential. Modern structural concepts demand reductions in both the weight as well as the cost of the production and fabrication of materials. Aluminium alloys have gathered wide acceptance in the fabrication of light weight structures requiring a high strength-to weight ratio and good corrosion resistance.

0 kommentar(er)

0 kommentar(er)